Product Introduction

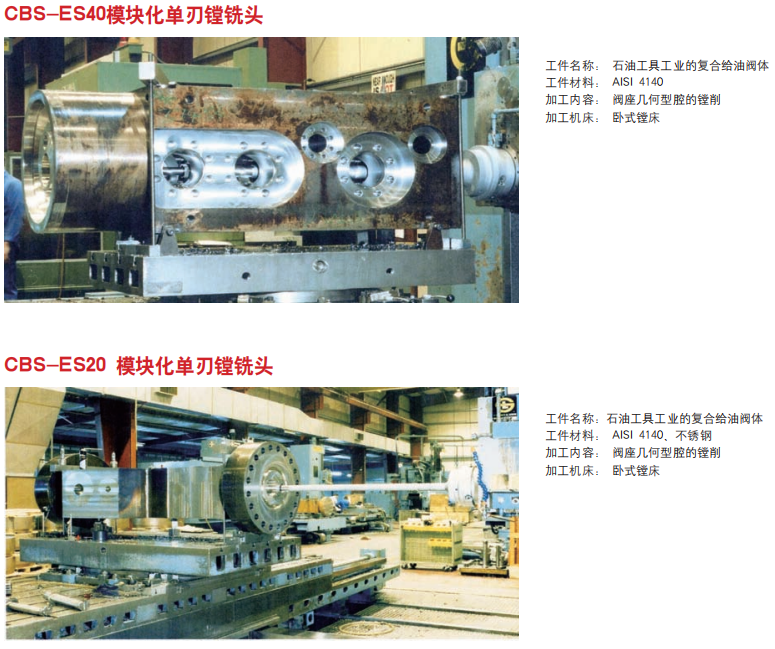

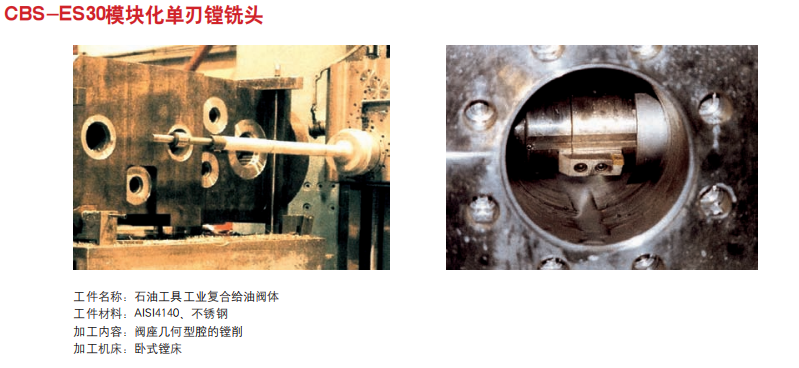

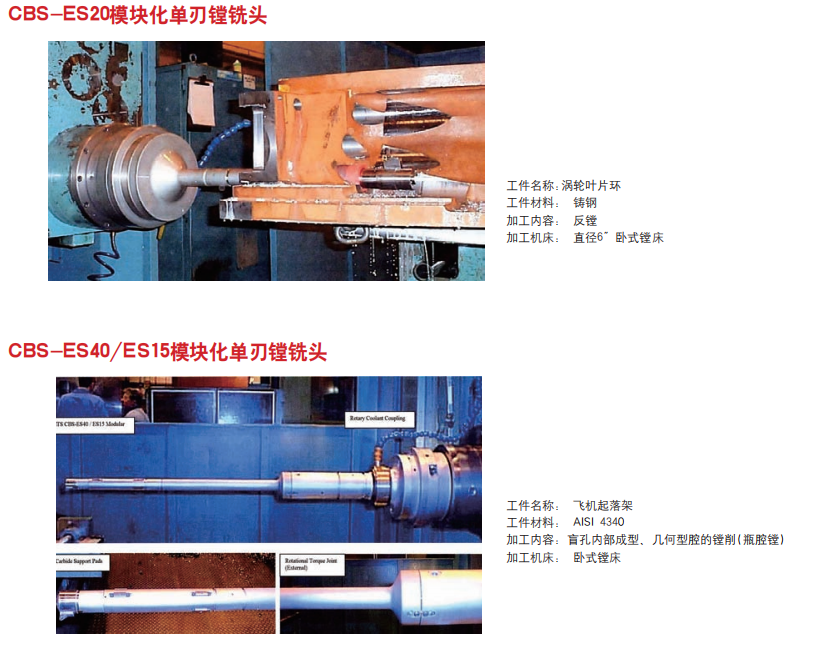

CBS ES is specially designed for the case where there is the requirement of lengthening function and the large workpiece is subject to high-speed forward and backward boring.

Therefore, it is an ideal tool for high-speed machining of valve body cavity, shutoff valve and hydraulic components.

The modular, long-stroke, CNC boring bar matched with this series of products is designed for rough machining, semi-finishing and finishing of valve body, shut-off valve and hydraulic components.

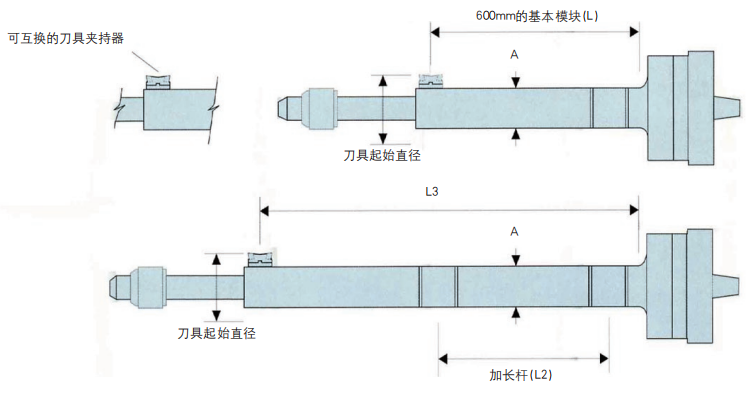

Each model of product is equipped with an interchangeable single-blade cutter head to process a certain range of diameters. However, some types of products can also use double-cutting edge cutter heads.

Designed for special performance

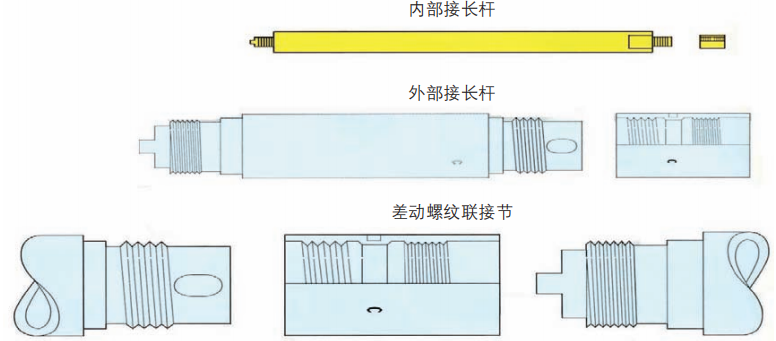

The differential thread design with positive lock connection is adopted on the boring head body and transmission connector interface.

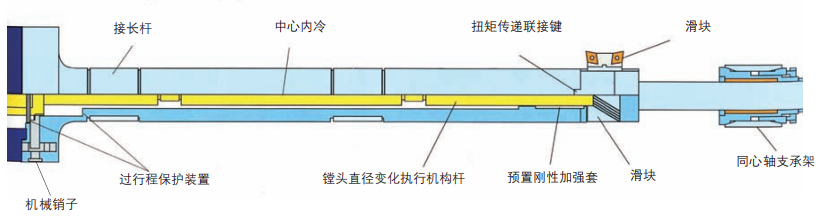

The precision of transmission connection is ensured by the diameter and end face of the precision grinding positioning circle and its good contact. The transmission of rotating power is realized by the transmission key or Hurth coupling on the outer part of the fuselage.

Because of the high rigidity of the design structure and the large contact area between the teeth at the bearing sleeve with preload and the transmission/slider interface, it can ensure that when cutting with the cutting edge, it can directly obtain high dimensional accuracy, surface finish and flatness.

Boring head parts are made of good materials, such as carbon steel, stainless steel, chrome-nickel alloy and various nickel alloys, so the above characteristics can be guaranteed.

Transmission/slider interface

In the whole machining process, the multi-tooth design structure of ITS CNC variable diameter boring and milling head system can ensure a very large tooth-to-tooth contact area. This enables its mechanical device to maintain particularly good linear displacement characteristics throughout its entire travel, and achieves the highest accuracy, repetition accuracy and production efficiency of the geometric contour processing of the CNC variable diameter boring and milling head system.

This design can also ensure that the rigidity reaches the maximum value when the stroke reaches the end point (when the cutting force reaches the limit value).

ITS products can also be customized according to user requirements to meet special modification and processing needs.

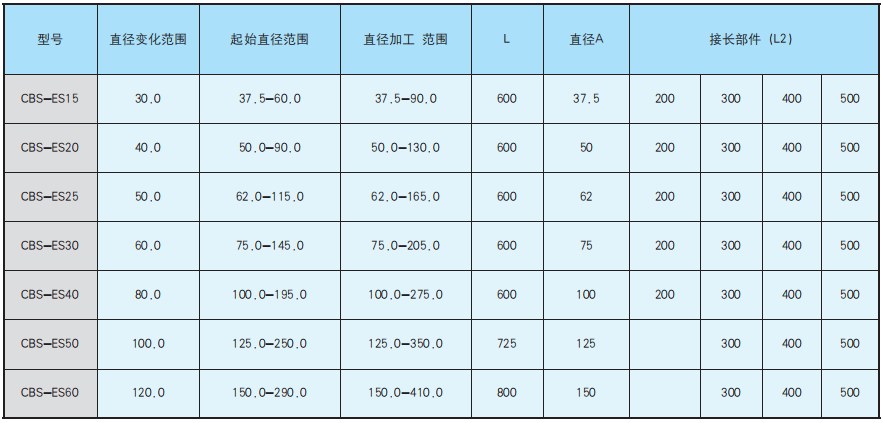

The processing range of a selected cutting head is obtained by adding the initial diameter and the diameter change. For example, the initial diameter of CBS-ES30 boring head is 75mm, the diameter variation range is 60mm, and its processing range is 75mm to 135mm. Therefore, using a variety of different types of cutting tool heads, the diameter processing range of CBS-ES30 will be larger, ranging from 75mm to 205mm.

Because this system is modular, the length of cutter bar of each model can be changed to meet different processing needs. The specific method is to install at most two extension parts on the basic components. For example, adding a 500mm extension ("L2") to a 600mm basic element ("L") can make the total length of the tool bar reach 1100mm ("L3").

Technical parameters of CBS-ES series products

*If the technical parameters of ITS boring head CBS series are changed, Zhengke Company will not notify otherwise.

Previous

Next

Previous

Next

Inquiry