-

About Horma

-

Product Introduction

Micro products are specially designed for a variety of complex and variable precision small hole boring.

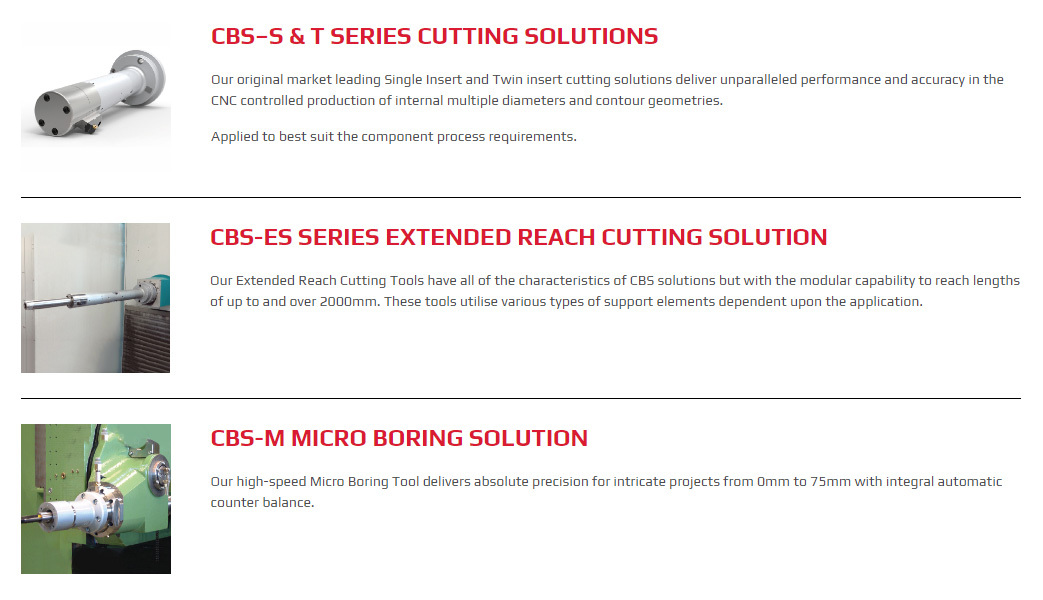

This versatile CNC variable bore boring and milling head system (CBS) greatly improves the machining efficiency, accuracy and flexibility of precision boring processes.

At the same time, thanks to the use of CBS Micro products and a unique boring bar, it is possible to boring all holes with a diameter variation of 32 mm.

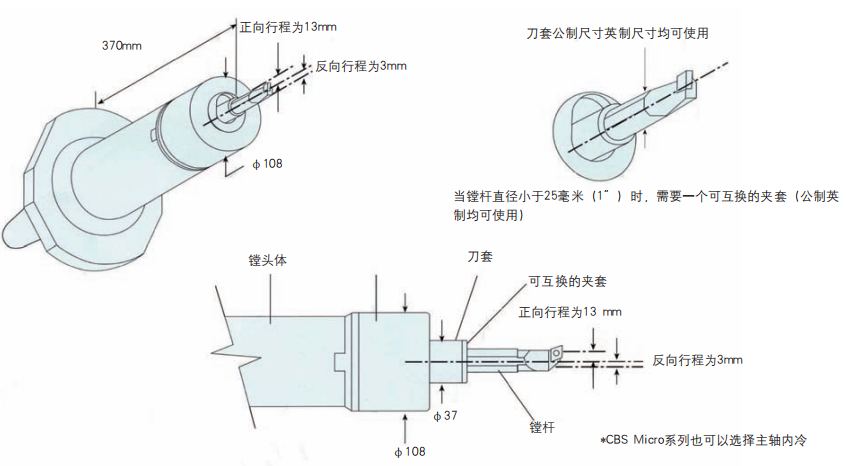

Its precise internal balancing mechanism controls the cutting diameter by means of double slide rails: one of them is equipped with interchangeable tool holders; The other is used as a counterweight. Its total sliding stroke is 16mm, of which the maximum radial stroke range is -3mm~13mm. In this way, the size of the processing can be made up to 0mm using Micro products.

The Micro series uses a variety of unique tool holders, and its actual cutting diameter range is determined by the size and type of interchangeable tool holders selected each time. The system is versatile and Micro products with a complete range of standard knife holders can process geometric contours, cylindrical and tapered threads of any diameter from 0mm to 75mm.

Micro products can be customized by users according to the following principles: can improve the utilization rate of users' existing machining tools; It can improve the flexibility of machining using cutting edges.

CBS MICRO

CBS MICRO Series

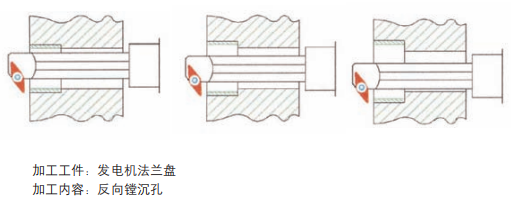

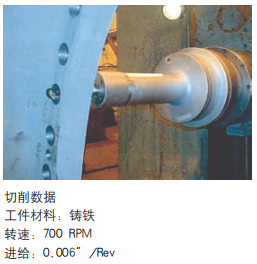

Application example: counterboring counterbore

- The boring tool slider is in the retracted position and quickly passes through the pre-machined hole to the starting position of counterbore.

- Adjust the boring tool slider to the first cutting diameter, counterbore the counterbore, retract the slider after counterbore to the required depth, and return the boring tool to the initial position of counterbore.

- Adjust the boring tool slider to the second cutting diameter, counterbore the counterbore, retract the slider after counterbore to the required depth, and return the boring tool to the initial position of counterbore.

- Adjust the boring tool slider to the final machining size, reverse boring counterbore, and chamfer and round.

- Retract the boring tool slider and quickly exit the boring tool.

Previous

Next

Previous

Next

Inquiry

Inquiry

After receiving your message, we will arrange personnel to contact you as soon as possible

Horma Group

Developing with National Industry

WIN-WIN TOGETHER

Service Hotline

Copyright © 2023 Beijing Sciencing Technology Co., Ltd.

Business license Powered by 300.cn Beijing