Product Introduction

ITS CBS S Series

ITS CBS S Series

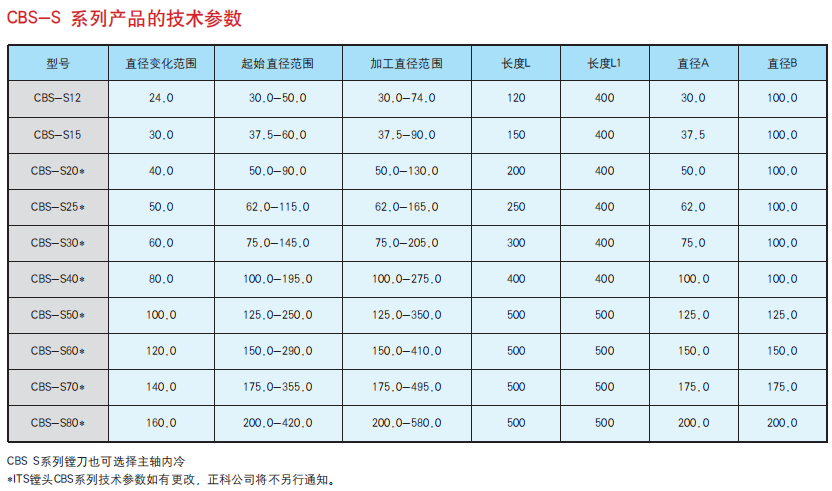

CBS S series products are specially designed for the case of large radial travel and high-speed forward and backward boring. Therefore, it is an ideal machining tool for high-speed machining of complex geometric profiles, multi-diameter stepped holes and multiple holes with different diameters.

CBS series products can be used for any machine tool that can provide both Z-axis and W-axis movement. It can be used for a single machine tool working independently, or for a processing unit in a production line.

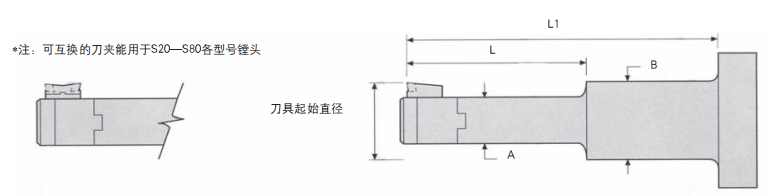

Each model has interchangeable single-cutting edge tool heads to process a certain range of diameters. ITS products can also be customized according to user requirements to meet special modification and processing needs.

The processing range of a selected cutting head is obtained by adding the initial diameter and the diameter variation range. For example, the initial diameter of CBS-S30 boring head is 75mm, the variation range of processing diameter is 60mm, and its diameter processing range is 75mm to 135mm. Therefore, the diameter processing range of CBS-S30 will be larger (75mm to 205mm) with a variety of different cutting tool heads.

*Please consult Beijing Zhengke Company for details.

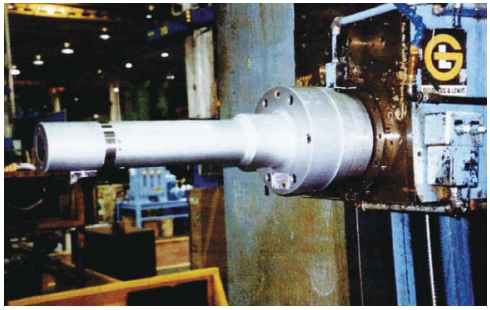

CBS-S50 single-edge forward and reverse boring and milling head

CBS-S50 single-edge forward and reverse boring and milling head

Workpiece name: single-hole valve body

Processing content: Boring of hole and end face of geometric cavity of valve seat

Workpiece material: steel

Machining machine: horizontal boring and milling machine

CBS S Series

CBS S Series

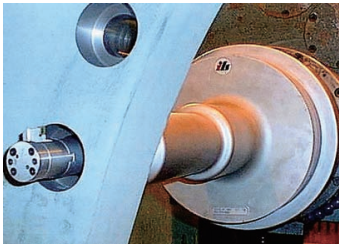

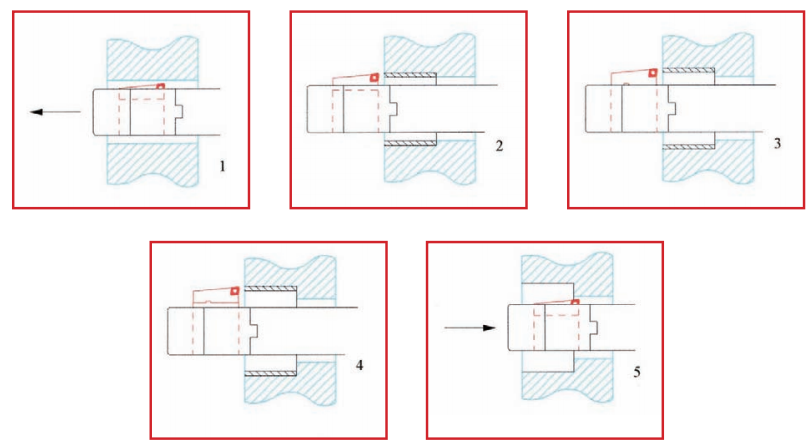

Application example: counterboring counterbore

1. The boring tool slider is in the retracted position and quickly passes through the pre-machined hole to the starting position of counterbore.

2. Adjust the boring tool slider to the first cutting diameter, counterbore the counterbore, retract the slider after counterbore to the required depth, and return the boring tool to the initial position of counterbore.

3. Adjust the boring tool slider to the second cutting diameter, counterbore the counterbore, retract the slider after counterbore to the required depth, and return the boring tool to the initial position of counterbore.

4. Adjust the boring tool slider to the final machining size, reverse boring counterbore, and chamfer and round.

5. Retract the boring tool slider and quickly exit the boring tool.

Previous

Next

Previous

Next

Inquiry