-

About Horma

-

Product Introduction

CBS SX series products are specially designed for the situations that require a wide range of radial control over a long distance to carry out forward and backward boring and end plane machining. Therefore, it is an ideal tool for high-speed machining of complex geometric profiles and multi-diameter holes. Its advantages are very prominent when machining large-diameter workpieces, such as turbine engine block, inner taper hole of rudder and base of large engine.

The working principle of this machining scheme can also be used for cavity boring of aircraft landing gear.

CBS SX series products are efficient CNC boring head system with single cutting tool head derived from "innovative machining scheme". It has the function of wide range radial control over a long distance. This kind of super large CNC boring bar is designed for rough and fine machining of large diameter and multi-diameter holes. A typical example is the generator parts mentioned in this article. Each model of product is equipped with a brand-name quick-change tool handle to process large-diameter workpieces in a specific range.

Designed for large range and extended length processing

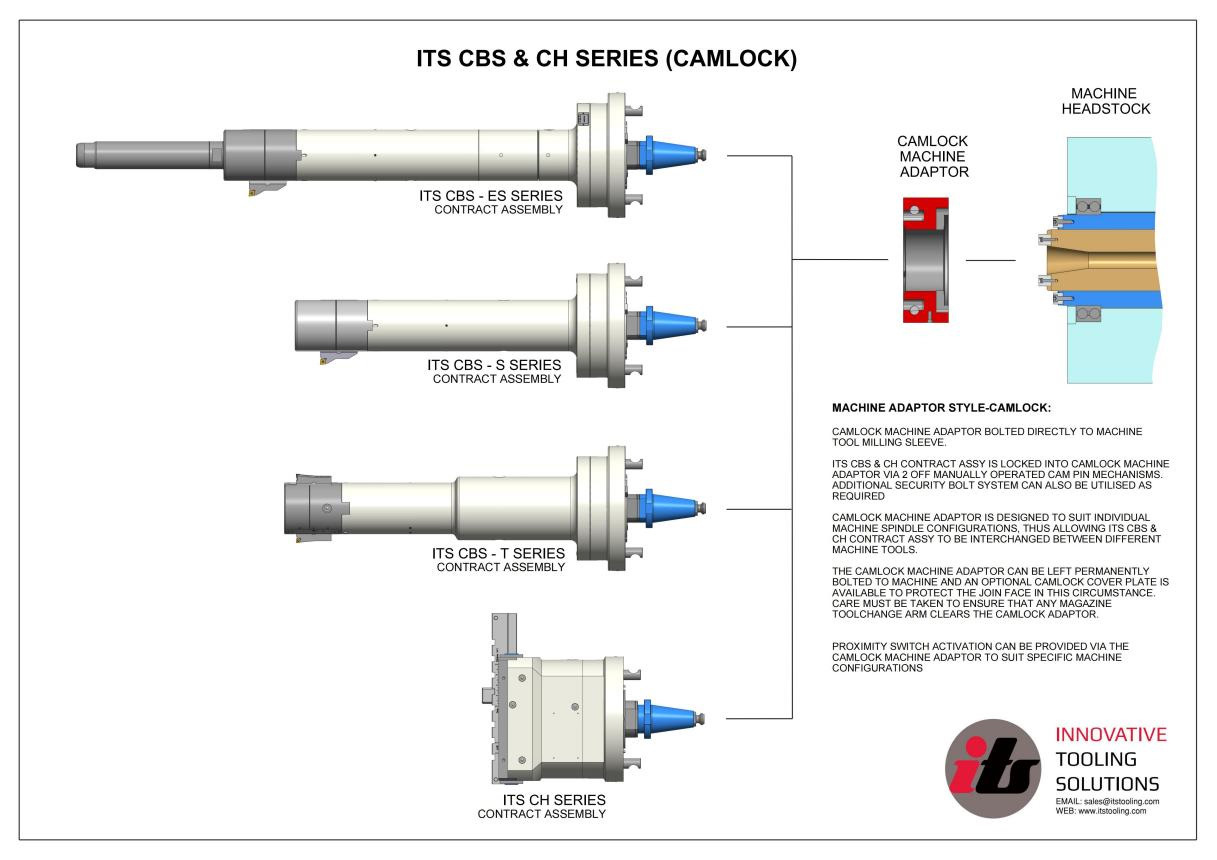

The specific specification of each product depends on the workpiece to be processed and the processing machine tool. The boring bar itself consists of three parts: bearing sleeve, boring head with diameter control and an optional support guide bar.

Bearing sleeve

The non-rotating bearing sleeve of SX series is directly fixed on the machine tool. The bearing sleeve is also equipped with tapered roller bearing and Wiper seal inside. The inner sleeve of the bearing seat sleeve is connected with the boring head which is undergoing boring and plane processing. The rotating torque is transmitted to the boring head through the inner shaft sleeve installed on the milling sleeve (or the rotating shaft sleeve equivalent to the milling sleeve). If necessary, additional support bushings that are suitable for the length of the bearing sleeve can also be provided.

Tool

Using the standard tool of all ITS tooling products - CNC boring device, the radial motion of the boring slide of SX series products is driven and controlled by a double (top and bottom) multi-cam device. This device uses a standard taper handle (or equivalent) installed on the boring bar of the machine tool, and uses this CNC axis for motion control.

CNC boring and surface machining tool heads are installed on the cutting head together with a unique quick-change tool system. The range of cutting diameter can be further expanded by using the standard tool lengthening system.

Guide device

According to the processing requirements, a guide device can be installed on the SX series boring head, which provides a supporting element for the required lengthening system. The guide device provides support through bearing elements that can be placed in the workpiece or fixed.

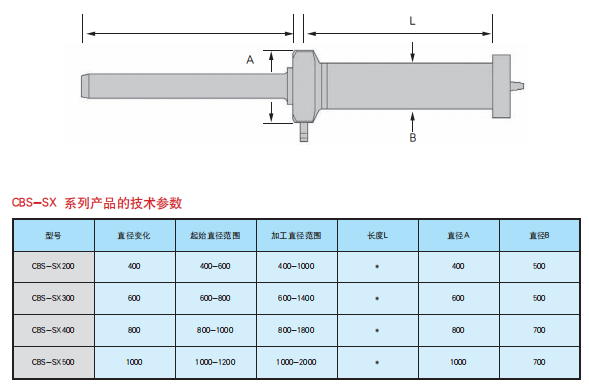

CBS SX series CNC variable diameter boring and milling heads have many different models.

ITS products can also be customized according to user requirements to meet special customer needs. The processing range of a selected cutting head is obtained by adding the initial diameter and the diameter variation range. For example, the diameter variation range of CBS-SX300 boring head is 600mm. If the initial diameter of cutting head is 600mm, its diameter processing range is 600mm to 1200mm.

Using a variety of different types of cutting tool heads or changing the unique quick-change tool system, its diameter processing range will be larger (600mm to 1400mm). The diameter and length of the guide rod shall be determined according to the application. Various connection and matching modes can be provided to adapt to table and floor horizontal boring machines with traditional head rest or ram extension head rest.

Please consult our company for details.

Previous

Next

Previous

Next

Inquiry

Inquiry

After receiving your message, we will arrange personnel to contact you as soon as possible

Horma Group

Developing with National Industry

WIN-WIN TOGETHER

Service Hotline

Copyright © 2023 Beijing Sciencing Technology Co., Ltd.

Business license Powered by 300.cn Beijing