14

2022

-

02

Re/Grant calorimeter has arrived at the user's factory!!!

Source:

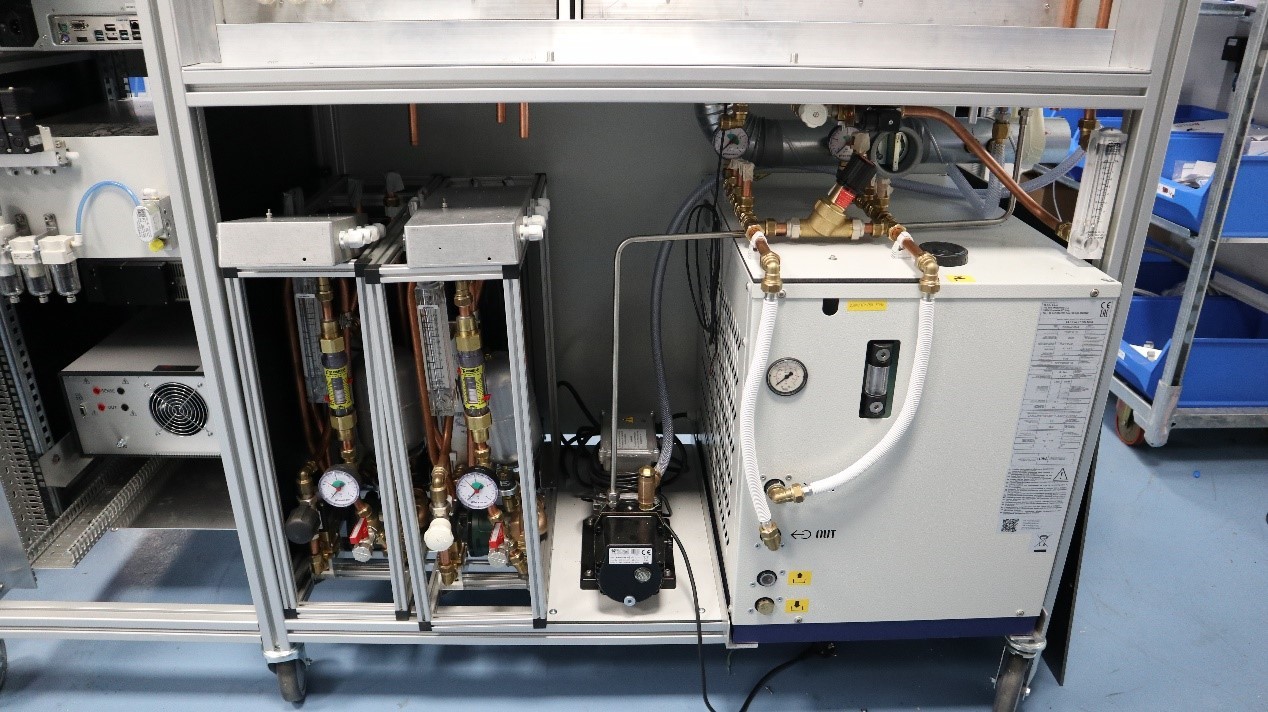

Recently, the Dutch Re/Grant refrigerator compressor calorimeter purchased by a compressor company from our company has successfully arrived at the user's laboratory.

In the workshop of Regent in the Netherlands, engineers will assemble and test the calorimeter according to the requirements agreed with customers in advance:

After the installation and test of the equivalent hot bench are successful, the Netherlands will pack and ship:

Re/Grant calorimeter arrived at the user's site:

Technical configuration of calorimeter:

The calorimeter can meet the test requirements of refrigeration capacity, mass flow, input power, COP value, primary side (input of frequency converter board) working current, voltage, frequency, power factor and efficiency, secondary side (output of frequency converter board) voltage, current, frequency, shell temperature, suction temperature, exhaust temperature, suction pressure, exhaust pressure, compressor speed and ambient temperature of household hermetic compressor within the range of 10W-750W, Compatible with R600a, R290, R134a refrigerant.

This calorimeter can test both constant speed and variable speed compressors.

Technical configuration of calorimeter:

- After manually loading the compressor into the test station and inputting the compressor test number and test working condition, the compressor refrigeration performance tester can automatically complete the vacuum pumping, leakage test and automatic start of performance test, and the working condition is automatically adjusted to the completion of the test.

- Frequency converter power measurement: measure the power between frequency converter and compressor by using three-phase power meter; The compressor speed can also be measured.

- Speed control of variable frequency compressor: There is a USB interface in the compressor compartment for connecting the d-BUS converter to control the speed of the compressor. The 5V square wave signal of automatic control frequency is also provided to control the compressor speed.

- The electrical control system is controlled by industrial personal computer, and all control processes are carried out in combination with NI data acquisition system and Labview software. All electrical control circuits are equipped with air switches for short circuit protection, all motor loads are equipped with thermal relays for overcurrent protection, the power supply circuit of the tested compressor is equipped with regulated power supply, and the power supply circuit is equipped with leakage protection function.

- The data acquisition and processing are controlled by a computer, which can instantly collect, display and process the data such as evaporation temperature, suction temperature, exhaust temperature, condensation temperature, supercooling temperature, compressor shell temperature, compressor ambient temperature, calorimeter ambient temperature, condensation pressure, evaporation pressure, second refrigerant pressure, compressor electromechanical parameters, calorimeter input electric energy, and automatically calculate the refrigeration capacity, input power, current COP value, shell temperature, mass flow rate, various parameter curves, and print a complete test report in Chinese and English together with other parameters

- Repeatability of refrigerating capacity: the accuracy corresponding to refrigerating capacity ≤ 40W is ± 1% of the reading, the accuracy corresponding to refrigerating capacity ≤ 100W is ± 0.5% of the reading, and the accuracy corresponding to refrigerating capacity > 100W is ± 0.3% of the reading

keyword: