High precision and easy to handle tiny inner hole

The goal of Microcut Ltd. is to develop tools, standard grinding machines and polishing machines to process rough inner holes with a diameter of 0.015-2.5mm by flexible activation method.

Micro Bore Sizing (MBS) is designed to provide integrated, easy to operate, comprehensive machine tools, tools and services.

Advantages of MBS process

|

|

High quality specifications

|

- Simple machine tool design saves downtime and maintenance time

- Stable process with high repetition accuracy

- The coating is applied to the tool to reduce the loss and thus increase the life of the tool

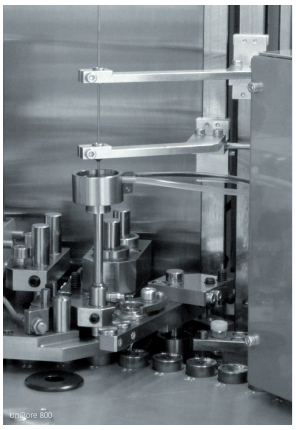

- The measuring instrument can eliminate the correction and loss on the station

|

|

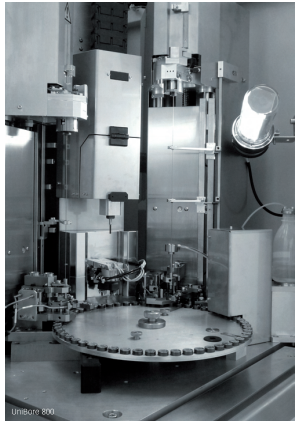

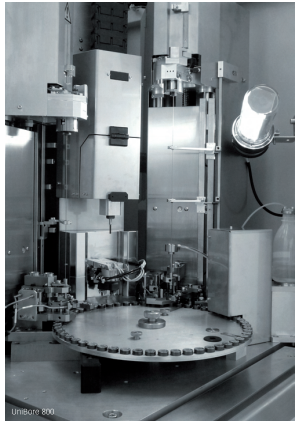

The workpiece produced by the UniBore800 machine tool can meet the following strict tolerances:

- Bore diameter tolerance (+/- 0.5 μ m)

- Roundness (< 0.1 μ m)

- Cylindricity (< 0.4 μ m)

- Parallelism (<0.4 μ m)

- Surface finish (Ra < 0.02 μ m)

|

Introduction to machine tool

|

|

Advantages of machine tools

|

- Open machine design to select the required configuration

- Can be processed on the old machine tool

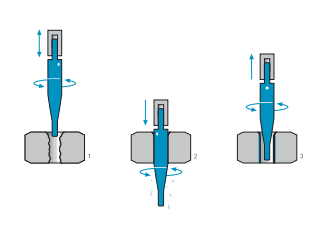

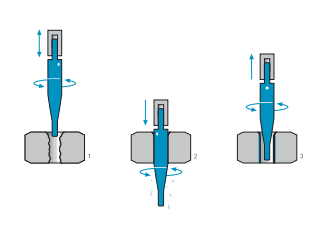

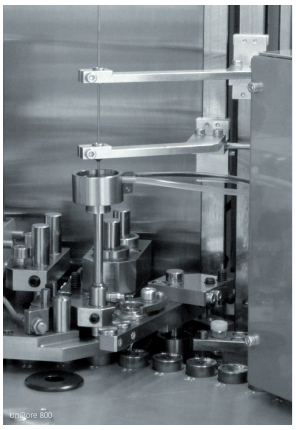

- MicroHead: can process single-sided taper tool

- Rotate and swing on the workpiece

- Pressure control mechanical process

- Multi-functional process, grinding, polishing, deburring

|

|

- Station correction: roundness, cylindricity, straightness

- Grinding size and accuracy

- Achieve a high level of surface finish

- The setting of the workpiece will not be changed

- Only the minimum machining tolerance is required

- Control quality synchronously during processing

- Flexible and variable processing procedures

- Grinding amount is about 2-200 μ m. Depending on the inner hole diameter, hole length and material

- MicroHead can be used as a tool (grinding or polishing)

- (Polishing process): Hard materials can be effectively processed to achieve the best surface roughness

- (Grinding process): applied to hard and soft materials

|